The Future We Envision

A future filled with hope,

from Nitto Seimo

Toward a future of

resource recycling

Aiming to realize a society that reduces waste and makes effective use of resources, we are working on such projects as the development of fishing gear made from environmentally friendly materials, the refurbishment of discarded fishing gear, and the effective use of manufacturing scraps.

copper alloy meshes

Conventional fish cages, which have been primarily made of polyethylene (PE), can be replaced with copper alloy meshes that are easy to recycle. Copper alloy prevents the nets from getting soiled, allowing them to be used longer and reducing maintenance work.

recycling

Working together with a material manufacturer, we have succeeded in recycling old, discarded fishing nets into new nets, an industry first. Resolving issues such as reductions in strength and durability, we have achieved a recycled fishing net with physical properties comparable to one made with 100% virgin materials.

discarded fishing nets

We are working to remedy the issue of so-called “ghost gear,” discarded and abandoned fishing gear drifting in the ocean. Our project to upcycle discarded fishing nets into fashionable bags that can be used for outdoor activities has attracted much attention.

scrubbing brushes

We are cooperating with a local company’s project to reduce resource waste by taking the scraps from the net manufacturing process and turning them into scrubbing brushes available for commercial sale. We have provided scraps generated during the production of the purse seine nets to this company free of charge.

Toward a sustainable

fishing industry future

Conventional fishing operations may generate marine refuse and cause water pollution during operations, and fishing has sometimes had a harmful effect on the marine environment. To remedy this situation, we are developing a variety of technologies.

Calm coastal waters suitable for aquaculture can become polluted by the sedimentation of the feed used for farmed fish. By providing composite technologies that enable offshore aquaculture, we have expanded the number of potential aquaculture sites and are contributing to the reduction of water pollution.

Damage to laver cultivation sites by birds and fish is becoming a serious issue, with losses estimated to be in the billions of yen in Japan. We manufacture and sell nets specially designed to prevent damage from fish such as black seabream. Laver cultivation businesses are adopting these nets, particularly in the Setouchi area.

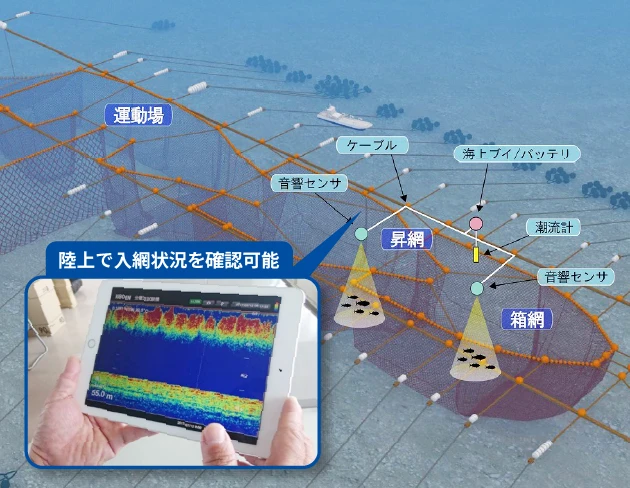

We develop and provide technologies to improve the efficiency of fishing operations through the use of IT, such as set net positioning simulations, a fish monitoring system for set net fishery, and a system for calculating and visualizing fishing net shape and force loads in the water.

from styrofoam to HDPE

The float material that has conventionally been used in fisheries can deteriorate and break down after a few years, becoming marine refuse. In order to stop the spread of such ocean waste, we independently developed and offer floats made of HDPE, a material with an outstandingly long life span.

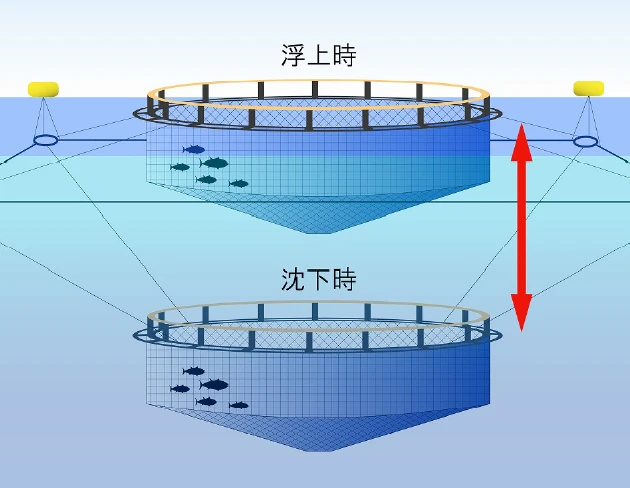

Conventional oyster rafts are sometimes destroyed by typhoons, creating drifting refuse. Our oyster rafts offer submersible operation, enabling them to be submerged during stormy weather to prevent damage, reduce loss of mature oysters, and prevent the generation of marine refuse.

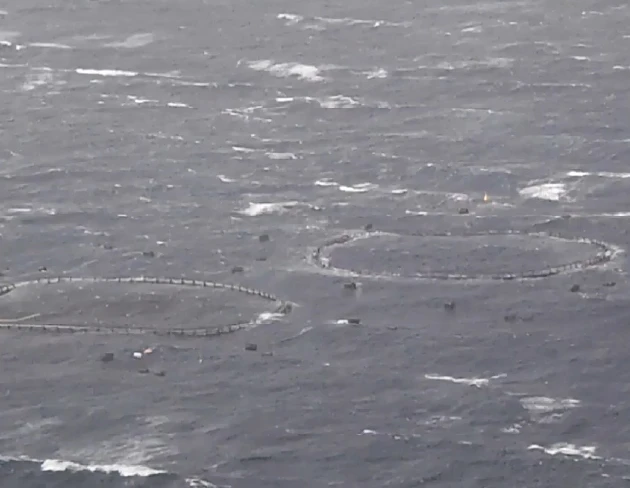

We have developed a technology that allows fish farming to take place in waters with more severe waves and currents that were previously considered unsuitable to the aquaculture business. We have created the world’s first large-scale submersible fish cages, whose depth can be adjusted to make them float or sink at will. This technology is contributing to the stabilization of the aquaculture industry.

Toward the future of

forest conservation

The range of nets we offer extends beyond the fishing industry. We offer products and ideas for reducing environmental impact, such as nets made from a plant-based fiber (PLA) that is carbon neutral.

Netting is used to protect saplings immediately after planting from damage by animals, but once the trees have grown and the nets are no longer needed, they must be removed. We manufacture and provide biomass nets that eventually biodegrade in the environment and can be left where they are placed without the need for removal.

Until now, synthetic fiber nets used in agriculture have required entangled plants to be separated from the net before disposal after crop harvesting, but we now manufacture and offer nets made of 100% natural materials. These nets can thus be incinerated as-is after harvesting.

Toward a future of

global coexistence

In the future that lies before us, no country will be able to pursue abundance on its own. By providing our fishing industry technologies and expertise to countries overseas, we aim to help increase the standard of living around the world.

At the request of the government of Papua New Guinea, we participated in a project to introduce small-scale set nets, a fishing technology unique to Japan, in the country and improve the lives of local people. We were also involved in inviting fishing business operators to Japan to take part in training programs.

As a project to assist reconstruction in the Philippines after the country was severely damaged by a once-in-a-century super typhoon, we set up typhoon-resistant aquaculture fish cages. We also supported reconstruction through ongoing technical guidance and education activities.

Toward a future of

diverse working styles

Nitto Seimo has introduced flexible working styles so that each and every employee can do their jobs without difficulty. Having developed an environment and systems that make it easier to raise children while working, we have received “Kurumin” certification from the Ministry of Health, Labour and Welfare.

We have established a workplace environment where not only women but also men can feel free to take childcare leave. We provide explanations of relevant systems to eligible male employees and encourage them to make active use of them, and in FY2023, we achieved a 40% male childcare leave utilization rate.

Toward a future of

outer space

conservation

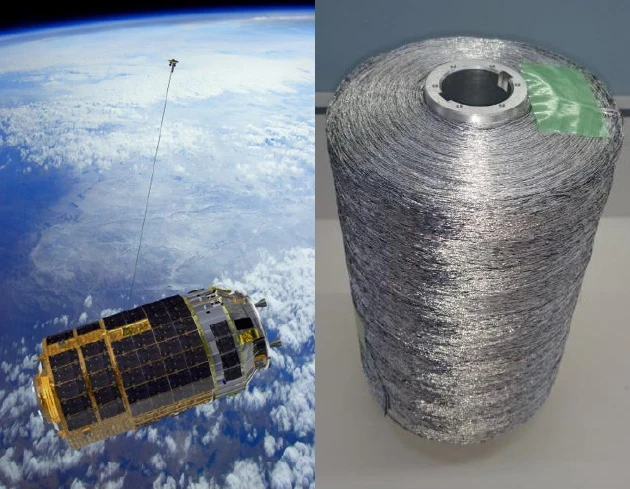

Nitto Seimo’s efforts are not limited to just our terrestrial environment. Our technology is also being used in the removal of space debris in Earth’s satellite orbit, which has become a problem as the development of space flourishes.

We are developing a debris removal system in cooperation with JAXA, Japan’s space agency. The core of this system, a rope-like conductive tether, employs our knotless net technology, and the development of the material was completed in 2015. Research aimed at demonstration testing is currently underway.